Challenges you may face when developing an Electric Drive Train

What challenges to overcome when developing an Electric Powertrain?

The world faces enormous challenges when it comes to energy and climate change. Energy-efficient Electronic Powertrains are contributing to combating some of these challenges. The race is on to develop efficient, economical and dynamic Electronic Powertrains and some of the figures been spent on research and development by companies based around the world is huge.

It appears that most countries have bought into reducing air pollution and the UK are one of those countries that want to be at the forefront of electric technology and has a target of ‘zero’ greenhouse gas emissions by 2050 as per this BBC article .

If the world is serious about meeting global energy and climate change challenges then replacing diesel or petrol engines with an efficient Electronic Powertrain is one of many innovations required to help reach that goal.

Modern Electronic Powertrains are a relatively new concept for some industries, especially the automotive industry and engineers are challenged with designing affordable, efficient and high-performing Electronic Powertrains as the industry undergoes a technological evolution.

The automotive industry is one area spending big to revolutionise the industry but in certain machine applications, Electronic Powertrains are in some cases the only option suitable due to the high torque demands at wheels and controllable requirements.

The Electric Powertrain is considered a relevant and competitive option to replace hydrostatic and hydrodynamic powertrains to increase energy efficiency. In mobile machines the Electric Powertrain could also improve the manoeuvrability and increase control accuracy so there are numerous industries that can benefit from the development of the system.

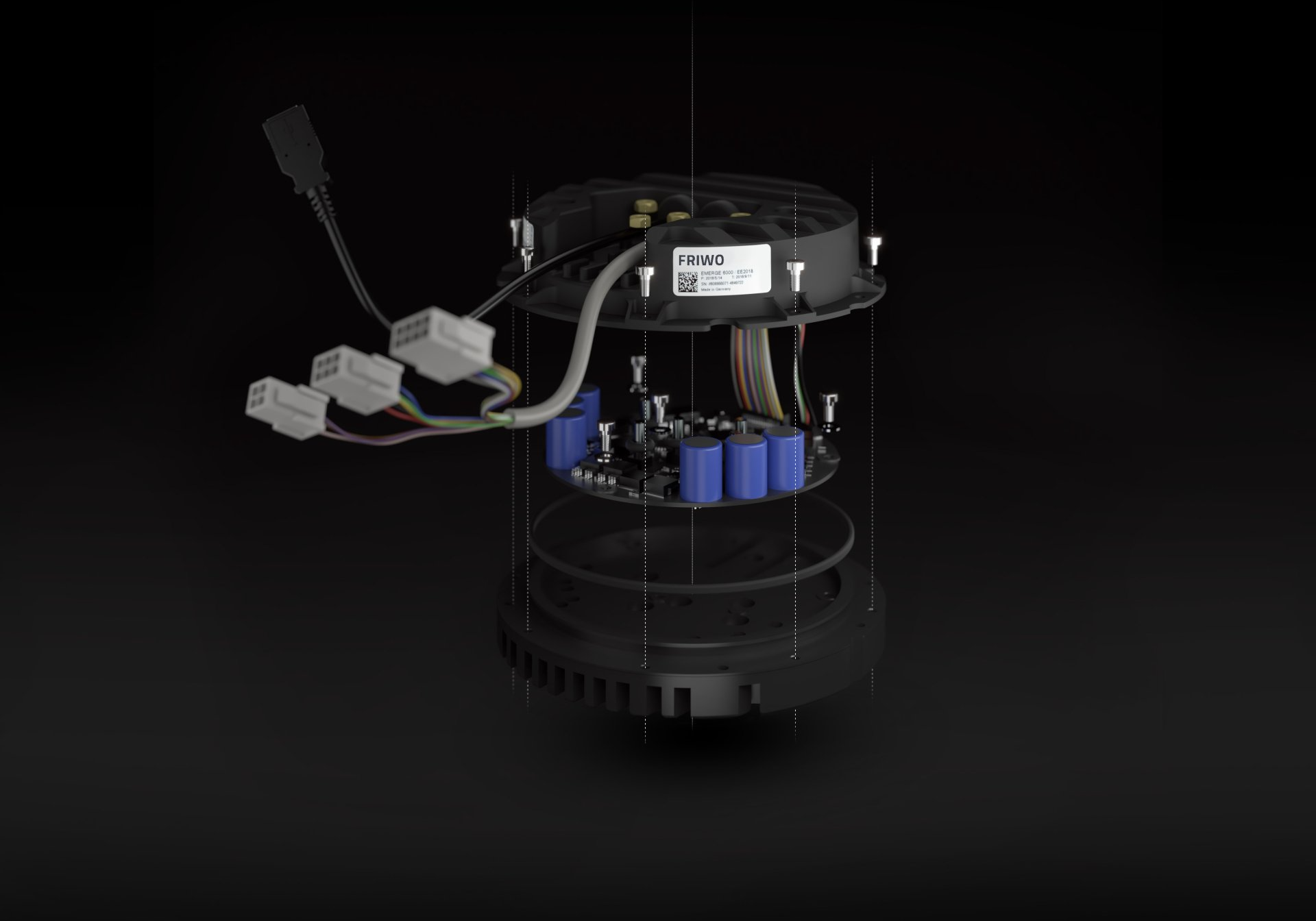

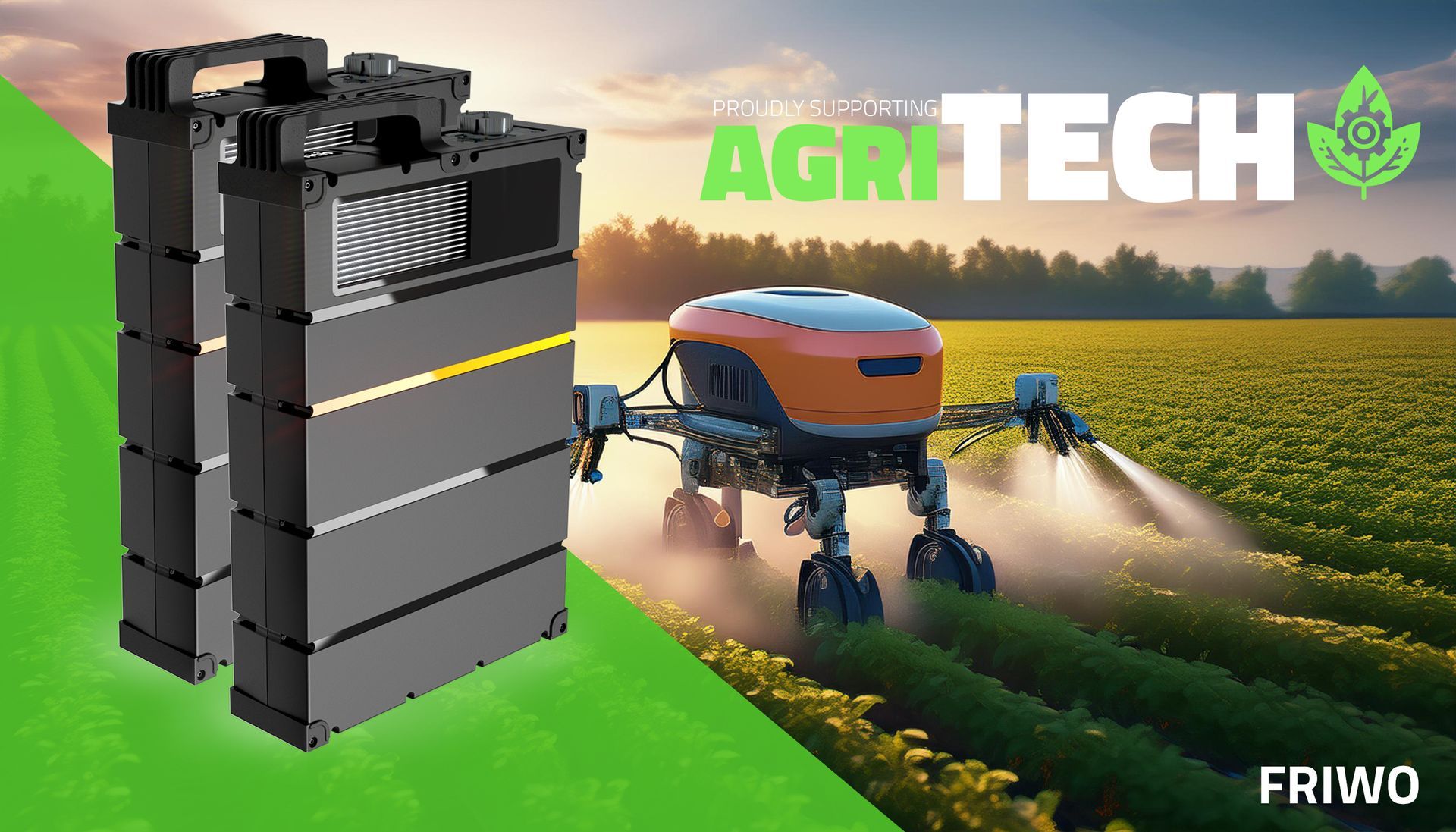

Whilst various industries are striving to develop leading Electric Powertrains, FRIWO have been busy in development and have combined all of their in-house speciality skills around power management and battery management to develop an Electronic Powertrain designed for mid-size vehicles and machinery. The FRIWO Electronic Powertrain is tried and tested and is already powering a fleet of hire scooters in Europe and due to the impressive system integration, software capabilities and agility, the fleet is co-ordinated entirely via an app.

The largest challenges faced developing an Electronic Powertrain can be split into 3 main segments:

1 - Range and charging speed

To meet range and acceleration targets, manufacturers need to work out battery sizing and explore motor and battery design trade-offs because a higher performing motor can lower the overall cell count for the battery pack. This is a very complex area especially when it comes to developing an Electronic Powertrain for high end vehicles wanting to quickly charge but yet reach distances of 200 miles plus.

Companies must develop and validate optimal charging algorithms and understand the impact of fast charging on their battery pack life. During charging, if the battery pack or charger temperature exceeds a critical temperature, the vehicle controller will reduce charging speed, lengthening the charging time. Thus, battery pack and faster charging electronics design, algorithm development, and thermal management go hand-in-hand.

2 – Performance and Lifetime

In the early part of the FRIWO development it was recognised that in-field reliability of the battery, motor, and power electronics were major concerns. It was recognised that maximum temperature and its distribution during in-field operations is a life-limiting stressor for components. There was a real need to account for not only material properties, but also tough-to-measure non-uniform distribution of current, voltage, magnetic flux, and temperature in these components.

Multi-domain data exchange within the FRIWO software at the early system design concept stage was therefore crucial. Integration and system-level exploits, if left for the later stages, would have resulted in design iterations and system integration problems.

3 - Integration

Optimising the integration of mechanical and electrical components into one Electronic Powertrain marrying each component of the Electronic Powertrain is the key to its efficiencies. Innovative simulation and optimisation software tools should be used early in the concept phase to assess optimal design variations.

At present, most Electronic Powertrains available comprise of separate entities such as the motor, battery, drive train and a vehicle control unit which are usually bundled together and what I have noticed is that taking this approach usually mean projects often run over or spiral over budget because work then starts on integration and it is the equivalent of drawing house building plans after the house is built.

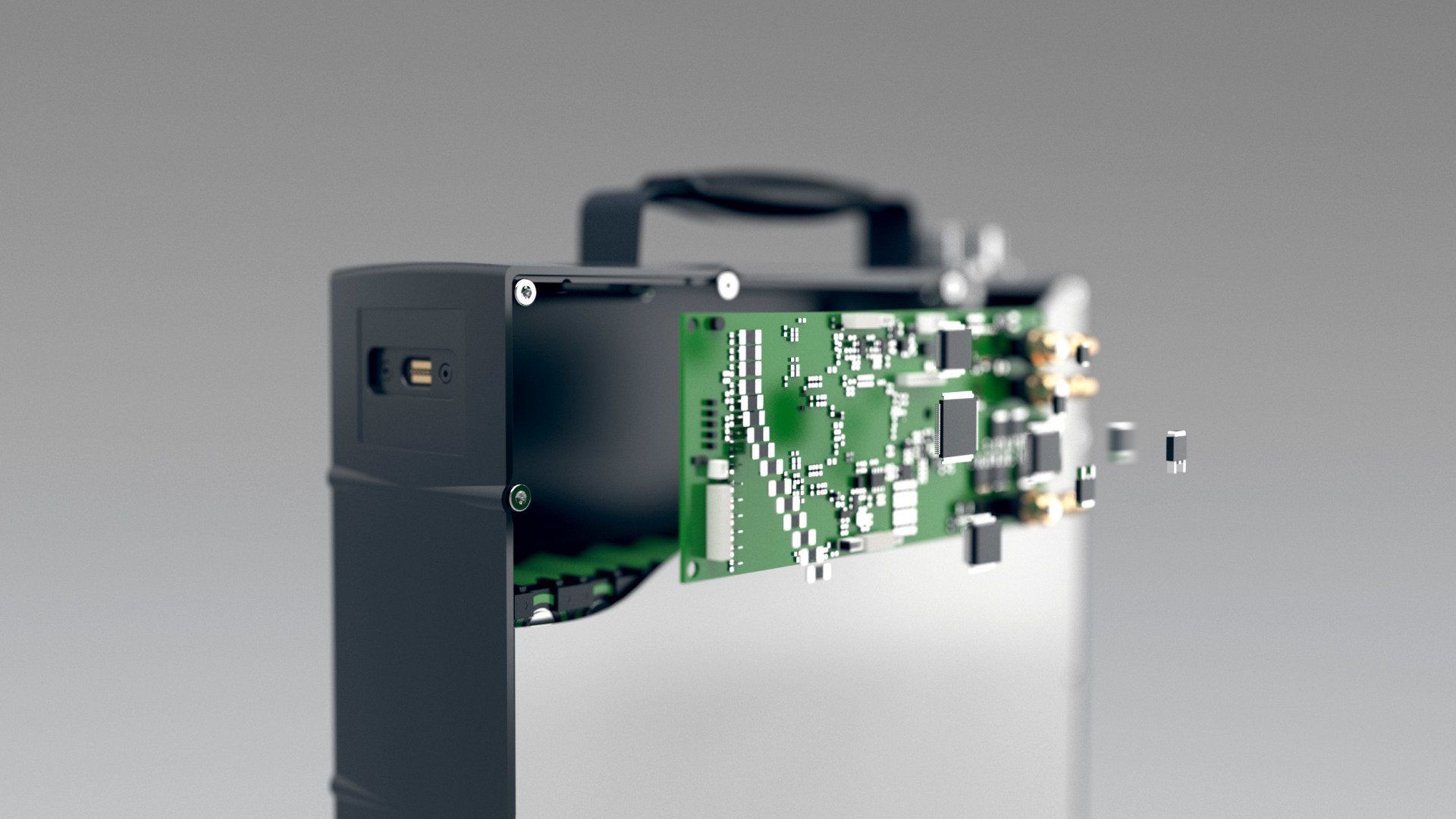

The FRIWO Electronic Powertrain has been designed with integration in mind right from the start and designed with the end user in sight. All components are tied into the software and in effect the whole Electronic Powertrain is powered by the software arming the end user or manufacturer with the flexibility to set parameters to suit the function of the vehicle or piece of equipment that it will power.

See the Electronic Powertrain in action!

The video shows a live demonstration of a Go-Kart containing the FRIWO Electronic Powertrain and it is been controlled by a mobile phone app via bluetooth.

The app in this situation allows you to control the vehicle output parameters as well as monitor vehicle performance using real time data.

To Summarise

There are many complex areas to developing an Electronic Powertrain. You simply cannot take the best components, bundle them together and expect to develop an efficient solution in super quick time. Haredata Electronics based in the UK have the perfect solution for mid-size vehicles developed by their German partners, FRIWO. The FRIWO Electronic Powertrain is very flexible and will provide the beating heart to any vehicle or piece of machinery, allowing you to focus on its design, reducing long term project costs, removing integration headaches and allowing efficiencies right across the solution!

Found something of interest?

Contact Us!

While you're here, why not read some of our other blog posts?

We are sure you'll find something interesting!