Haredata Application - Robotic Horticultural Products

December 13, 2019

Battery Charger meets extreme temperature requirements!

A major global manufacturer asked us to look at developing a range of battery chargers for their latest project, the next generation of robotic horticultural products. The products are built at the customers UK facility, but much of the engineering and specification work was in association with the European based product management team.

Application Specific Power Supplies

The application specific requirements were extreme by any standards:

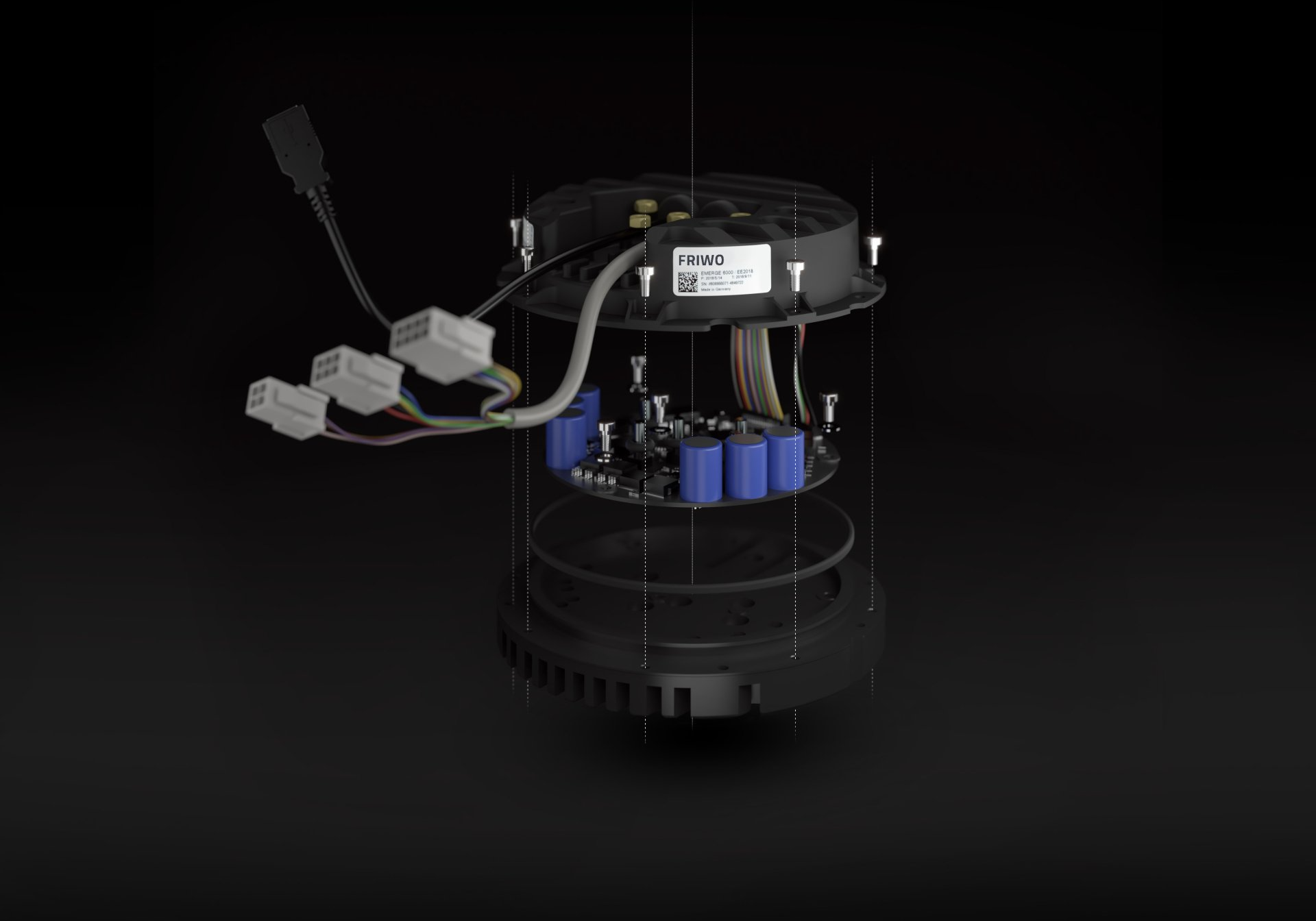

The working temperature range specified was from -30°C to +40°C and we carried out exhaustive testing to build this requirement into the customer specific design. The Chargers also had to be IP rated as they would be subject to the extremes of weather throughout the European region from the Barents Sea to the Mediterranean. To meet this operational concern we developed a partial potting process for manufacturing to ensure compliance. The Chargers also had to be UV tolerant and suffer minimal degradation over an extended lifetime. Extensive testing to confirm compliance was carried out both in the FRIWO R&D area and at the customers own test facilities. Despite these high parameters, there were also very strict condensation limits imposed at most extreme operating conditions at the design stage.

Finally, despite the somewhat rugged nature of the application, FRIWO still offered a nominal 200K hour MTBF as they do across the whole range of PSUs and Chargers. The customer now takes FRIWO Chargers for the majority of their robotic product range after successful and collaborative engineering work across the range.

We can help with your application too...

Found something of interest?

Contact Us!

While you're here, why not read some of our other blog posts?

We are sure you'll find something interesting!

In the relentless pursuit of a sustainable and electrifying future, the automotive industry is witnessing a monumental shift towards electric vehicles (EVs). As we pave the way for cleaner transportation alternatives, a crucial element in this transformation is the evolution of charging infrastructure. Enter the Battery Charge Station for modular EV batteries – a revolutionary concept that's redefining the way we charge our electric vehicles.

The key to a perfectly functioning overall system is the precise selection and detailed matching of individual components. To make sure that the process is a success we offer you a complete package: As a provider of drive technology systems we can deliver all the components required for a modern electric drive train from a single source – including the required control and service software.

The future of autonomous electric mobility is multifaceted. Graz University of Technology is fulfilling this reality by developing a universally applicable research vehicle that can be used both for simulating a mission to Mars and for rescuing people buried in avalanches. FRIWO accompanies this exciting project and provides strategic advice and supplies the drive and control technology.